Giới thiệu Trung tâm gia công tiện phay Hermle

Trung tâm gia công tiện phay Hermle C42

The C 42 machining centre from the High-Performance-Line makes for an effective entry into MT technology – and it becomes a high-performance milling and turning centre. This includes various applications in the tool and mould making, medical, aerospace, motorsport, racing machine sectors and other industries: TheC 42/ C C 42 U MT machining centre is at home in every area.

As a milling/turning centre, the C 42 / C 42 U MT responds to demands for highest precision and very small tolerances through its workpiece-dimension-optimized traverse paths and thought-through 5-axis usage. You can discover more details about the C 42 / C 42 U MT via the i-buttons in the 360 degree view.

Dimensions

Traverse path: 800 x 800 x 550 mm

Body: dia. 800 / H 560

Collision circle: dia.990 mm

Max. vertical table clearance: max. 700 mm

Facts

Speed: 15000/18000/25000/42000 1/min

Rapid traverse linear X-Y-Z: 45 (60)–45 (60)–40 (60) m/min.

Swivelling rotary table: dia. 800 x 630 mm

max. table load: 1400 kg

HIGH-TECH TOOL SPINDLES WITH COLLISION PROTECTION

The slimline tool spindles are constructed in two parts and can be replaced easily and quickly during servicing. Thanks to low interfering edges and collision protection by

compression sleeves, safety is given primary importance by maximum collision avoidance. Damage can be prevented in 50 % of collisions.

FROM A TO Z

Automatic cabin door, bed flushing, BDE-signal, electrical heat compensation, emulsion mist extraction system, precision packages, graphite machining packages, height-adjustable control panel, stainless steel production cabin, rotating visibility improvement unit, cooling unit, chip conveyor, coolant nozzle and chip cart, tool breakage monitoring and measurement, additional magazines …

IN MANUFACTURING AND OPERATION

Hermle manufactures many components using lightweight construction and mineral casting technology. The high degree of own production, local suppliers and components with high efficiency factors also promote energy efficiency. Energy recuperation, high-quality servo drives and the legendary long service lives are all proof of the same high standards during actual operation.

HEIDENHAIN OR SIEMENS

HeidenhainTNC 640 and Siemens S 840 D – these are the two control systems that can be used with the C 42 / C 42 U MT. They feature a variety of configurations and functionalities – including tools for improving precision for rotary and swivel operations, shell transformation and transparent tool management. Options such as Dynamic Efficiency, Dynamic Precision or the Kinematic Opt. software also serve to widen the range of functions.

WITH TOOL CHANGER AND SWIVELLING CONTROL PANEL

The pick-up magazine of the C 42 / C 42 U MTis integrated into the machine bed, making for very good accessibility. There are 42 magazine pockets which can be extended to 462 by means of additional magazines. The maximum tool weight is 8 kg and the maximum tool length is 300 mm. The tool magazine of this milling/turning centre is rounded off by the swivelling control panel and covers for the tool holding fixture.

LARGE PALLET CHANGER AND COMPLEX ROBOTICS

A genuine milling/turning centre such as the C 42 / C 42 U MT also fulfils all demands in respect of automation. This starts with the compatible PW 850 pallet changer that can serve components and pallets with especially large dimensions. Further options are HS flex and the RS 05 / RSL, RS 2 andRS 3 robot systems. Up to three peripheral devices can be connected with the C 42 / C 42 U MT in this way. If required, the HACS (‘Hermle-Automation-Control-System’) and the HIMS (‘Hermle-Information-Management-System’) can be used for easier operation.

EVERYTHING WELL THOUGHT-THROUGH

From the comprehensive fluid technology to the optimized chip management system and a range of cooling lubricant units to the hinged belt conveyor: The milling/turning centre of the High-Performance Line has a number of highlights to offer, e.g. the right chip disposal equipment for removing all types of chip from the working area. The C 42 / C 42 U MT can be transported without dismantling and set up without a foundation.

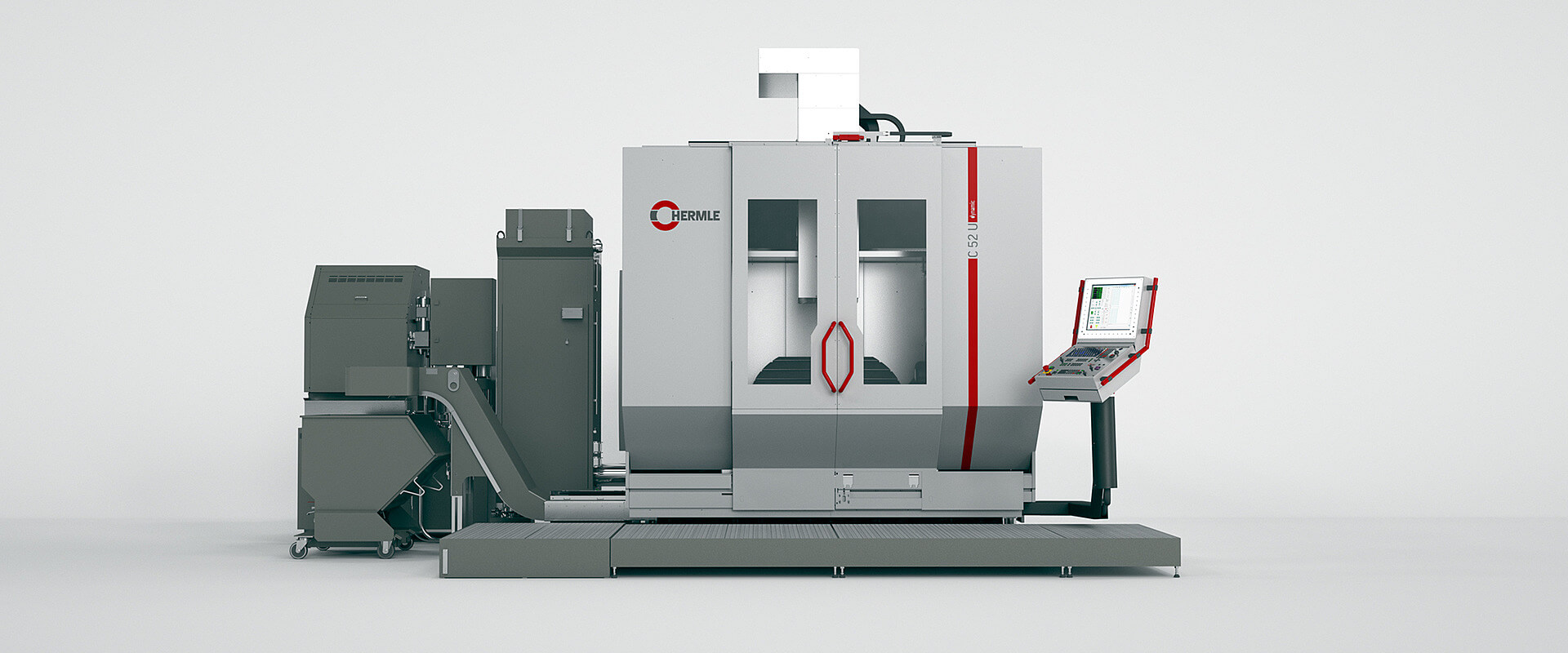

Trung tâm gia công tiện phay Hermle C52

Ample dimensions, high-performance spindle drives and many useful innovations for practical work turn the C 52 / C 52 U MT machining centre into a top performer. You can discover more details about the C 52 / C 52 U MT via the i-buttons in the 360 degree view.

FOR PARTS UP TO 2000 KG

Dimensions

Traverse path: 1000 x 1100 x 750 mm

Body: dia. 1000 / H 810

Collision circle: dia. 1290 mm

Max. vertical table clearance: 950 m

Drive & Co.

Speed: 9000/12000/15000/18000 1/min

Rapid traverse linaer: 60–60–55 m/min.

swivelling rotary table: dia. 1150 x 900 mm

Table loading max.: 2000 kg

HIGHTECH-TOOL SPINDLES

The slim tool spindles are constructed in two sections, making them easy to replace during servicing. Safety comes first with small collision edges and collision protection using compression sleeves. The C 52 is equipped with compact spindles. All spindles can be replaced quickly and easily during servicing. The spindles feature various speed ranges and different tool holding fixtures, making them suitable for a wide variety of machining tasks.

FROM A TO Z

Automatic cabin door, bed flushing, BDE-signal, electrical heat compensation, emulsion mist extraction system, precision packages, graphite machining packages, height-adjustable control panel with swivelling 19” screen, rotating visibility improvement unit, cooling unit, chip conveyor, coolant nozzle and chip cart, tool breakage monitoring and measurement, additional magazines …

IN MANUFACTURE AND OPERATION

Hermle manufactures many components using lightweight construction and mineral casting technology. The high degree of own production, local suppliers and components with high efficiency factors also promote energy efficiency. Energy recuperation, high-quality servo drives and the legendary long service lives are all proof of the same high standards during actual operation.

HEIDENHAIN OR SIEMENS

Heidenhain TNC 640 and Siemens S 840 D – these are the two control systems that can be used with the C 52 and C 52 U MT. They feature a variety of configurations and functionalities – including tools for improving precision for rotary and swivel operations, shell transformation and transparent tool management. Options such as Dynamic Efficiency, Dynamic Precision or the Kinematic Opt. software also serve to widen the range of functions.

WITH TOOL CHANGER AND SWIVELING CONTROL PANEL

The pick-up magazine of the C 52 / C 52 U MTis integrated into the machine bed, making for very good accessibility. There are 60 magazine pockets which can be extended to 325 by means of additional magazines. The maximum tool weight is 30 kg and the maximum tool length is 500 mm. The tool magazine of this milling/turning centre is rounded off by the swivelling control panel and covers for the tool holding fixture.

LARGE PALLET CHANGER AND COMPLEX ROBOTICS

With dimensions of 800 x 800 /⌀ 1000 mmor 1000 x 800 / ⌀ 1166 mm, the PW 2000and PW 3000 pallet changers are no lightweights – just what the high-performance C 52 / C 52 U MT likes. Also, the RS 2 and RS 3 robot systems can be connected with the machining centre, up to two peripheral devices at the same time. If required, the HACS (‘Hermle-Automation-Control-System’) and the HIMS (‘Hermle-Information-Management-System’) can be used for easier operation.

EVERYTHING WELL THOUGHT-THROUGH

From the comprehensive fluid technology to the optimized chip management system and a range of cooling lubricant units to the hinged belt conveyor: This High-Performance Line model has a number of highlights to offer, e.g. the right chip disposal equipment for removing all types of chip from the working area. This high-performance machining centre can be transported without being dismantled and set up without a foundation.

Trung tâm gia công tiện phay C 60

HERMLE HIGH-PERFORMANCE-LINE

CNC MACHINING AT THE TOP OF THE RANGE

Dimensions

Body: dia. 1200 / H 900

Collision circle: dia. 1400 mm

Max. vertical table clearance: 1100 mm

Rapid traverse linear X-Y-Z:50 m/min.

Swivelling rotary table: dia. 1350 x 1100 mm

max. table load: 2500 kg

HIGH-TECH TOOL SPINDLES WITH COLLISION PROTECTION

The C 62 is equipped with compact spindles. All tool spindles can be replaced quickly and easily during servicing. The tool spindles feature various speed ranges and different tool holding fixtures, making them suitable for a wide variety of machining tasks.

Hãy là người đầu tiên nhận xét “Trung tâm gia công tiện phay Hermle”